Alloy Fabrications

Marks Brothers has a well-earned reputation in alloy fabrication for quality, timeliness and competitive pricing. Its commitment to invest in the latest fabrication technologies, such as digital pulse welding and automated orbital welding, combined with the ongoing training and education of its highly-skilled craftsmen delivers the highest quality alloy fabricated equipment to its clients. Whether the need is for an Inconel 625 pipe spool, Hastelloy C-276 reactor, or a Zirconium clad shell and tube heat exchanger, Marks Brothers can make it. Some of the alloys it works with include:

300 Series Stainless Steels

6% Moly’s – AL6XN, 254 SMO, 904L

Austenitic Stainless Steels

Duplex Stainless Steels – 2205, 2101, 257

Ferralium 255

Hastelloy® C-276, C-22, C-200

Inconel – 600, 600H, 625, 800, 800H

Monel 400

Nickel Alloys

Super Duplex – Zeron 1000

Titanium

Zirconium

Note: Marks Brothers is always exploring new projects with different alloys. If your project needs a new or uncommon specialty alloy, ask Marks Brothers if we can make it.

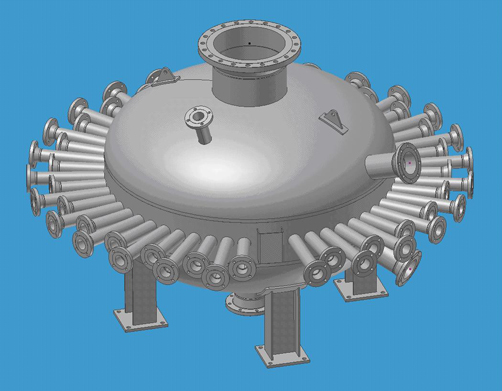

ASME Pressure Vessels

Operating in accordance with ASME Section VIII Div. 1, Marks Brothers designs, fabricates, and repairs ASME Pressure Vessels of all shapes, sizes and complexities. Its current authorizations allow it to produce vessels with “U”, “NBIC”, “R”, “S” and “H” stamping. It also manufactures tanks in accordance with ASME Section 1, API 650 and API 620, as well as providing non-stamped fabrications built in accordance with either the ASME Pressure Vessel Code or ASME Piping Codes (B31.1 & B31.3).

Marks Brothers furnishes pressure equipment for many international markets from Mexico, Central and South America to the South Pacific and beyond. Its certifications include Pressure Equipment Directive (97/27/EC) with a CE stamp for Europe, CRN’s for units shipping to Canada, and compliance with the Australian Code for Australia. Its fabrication and manufacturing center on the U.S. west coast, and proximity to three major ports positions Marks Brothers to ship to any international market.

ASME Pressure Vessels

Clad Vessels

Columns / Towers

Cyclones

Double Walled Vessels

Fermenters

Jacketed Vessels

Internal Components

Ladders / Platforms

Low to high pressure

Non-Code Tanks

Pipe Spools

Process Vessels

Reactors

Scrubbers

Separators

Shell and Tube Heat Exchangers

Skid Packages

Solid Alloy or Clad

Sterilizers

Storage Tanks

Skid Packages

CNC Forming

CNC forming means closer tolerances, faster production, and, ultimately, a better product. Whether the final product is a part (component) that is laser cut and formed, or a weldment containing formed pieces, Mark Brothers’ CNC forming capabilities allow it to deliver the highest quality parts faster and more economically.

CNC Rolling

Marks Brothers strives to offer its customers the most cost-effective and highest quality forming. To ensure the best rolling at lower costs, it added CNC-Rolling capability that delivers rapid production times, better tolerances, CNC measuring of material while rolling, and no layout time on tangents. Further, programs saved to a file library for repeat, minimized setup times for repeat jobs.

Common Rolled Shapes:

Pipe – round tube

Square or rectangular tubes

Flat or square bar

Angle with leg in or leg out

Channels

I-Beams

Extrusions

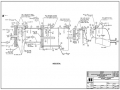

Engineering & Design

Marks Brothers’ engineering group has both the depth and the real world experience to better understand and serve customers’ needs. The company provides the capabilities of a large engineering firm, with a personal touch.

Design engineers at Marks Brothers provide mechanical designs of pressure vessels, thermal and mechanical designs of shell and tube heat exchangers as well as finite element analysis of highly stressed and critical components such as nozzles, lifting trunnions, flanged & flued expansion joints, and seismic applications.

The design engineering team’s commitment to apply the latest in processing technologies includes solid modeling in Autodesk Inventor and Solid Works. This allows them three-dimensional previews of parts and assemblies prior to creating detail drawings for manufacturing, and provides files to export to create the component parts.

Beyond engineering and drawings, Marks Brothers can provide P.E. stamping of designs and drawings when required.

Fabrication

Exceeding customer expectations in service, quality, and delivery is the cornerstone of Marks Brothers’ growth for three generations. Each generation has invested in new technology, larger facilities and additional services, spurring the organization to higher levels.

Marks Brothers has the depth, capabilities and experience to execute large and complex fabrication projects. To ensure the desired outcome, each project is based on a meticulous production plan from material handling, to kitting, fitting, welding, and testing.

Marks Brothers combines state-of-the-art fabrication equipment with experienced, highly trained fabricators, responsive project management, an engineering team utilizing the latest in design software, and a robust quality program second to none.

Let Marks Brothers take a look at your needs and come up with a solution together.

Half-Pipe Coils

With Marks Brothers’ continuous strip-shaping half-pipe coiling systems, it can provide half-pipe coils in multiple revolutions minimizing waste material and section welds.

Throat in or throat out, Marks Brothers can produce units from as small as 12 inches in diameter to the largest sizes needed.

In addition to half-pipe coils for shells, Marks Brothers has developed an advanced CNC methodology for rolling and cutting half-pipe coils for heads and cones. This approach delivers half-pipe rolled and cut at the precise pitch and radius of the applied location on the head or cone, saving the fabricator a tremendous amount of grinding and fitting compared to conventional methods.

Laser Cutting

Marks Brothers offers simultaneous cutting on multiple lasers with automated material handling systems and cutting capacities up to 6,000 watts. It also has created specific fixturing for cutting of structural shapes or pre-formed parts.

In addition to flat cutting, Marks Brothers has tube cutting production capability designed specifically for laser cutting tube and pipe.

Marks Brothers has the capability to create almost any configuration of holes, slots, notches or joints combining sheet metal tabs with tube slots for self-fixturing on frames and other weldments.

By utilizing customers’ Autocad, Autocad Inventor, or Solidworks files, Marks Brothers avoids duplication of work resulting in a faster lead times and lower prices.

In addition to laser cutting parts, Marks Brothers can apply any of the following processes to laser cut blanks:

CNC Forming

Dimples, Louvers

Reaming

Tapping

Hardware Insertion

Welding

Plating

Painting

Machining

Marks Brothers’ full service precision CNC equipment offers the latest in machining technology. Its investment in the best equipment delivers tighter repeatability on close tolerance parts, and higher quality and cutting capability on stainless and alloy machining. Marks Brothers’ machining capabilities include:

ANL3000Y / 700, the largest version of the Mori Seiki NL Series, delivering the following:

o 12” chuck

o 3.50” bar capacity through the spindle

o Turn up to 17” diameter

o Tailstock with 32” length capacity

o Built in Milling with 12 station Live Tooling

o 6,000 RPM on milling tools comparable to 40 taper mill

o Turn, drill, and mill features that achieve better run time and quality by not moving the part and not compromising quality and speed.

o Face, turn, groove, o.d. milling, face milling, threading, boring, drilling

Marks Brothers mills include:

Mori Seiki Dura Vertical 5100

Mori Seiki Vertical Mill NVX 7000

o 60” x 30” x 26” Z (distance from spindle to table is 34”)

o 50 taper Machine

o 10,000 RPM spindle without compromising accuracy

o Heavy hogging and fine finishing in the same machine

o Hard metals machining capability – Titanium, Inconels, die mold, stainless, steel, aluminum

o Ability to gauge work pieces inside the machine with a spindle probe

o High accuracy milling

o High pressure through spindle coolant for drilling and heavy cutting

Nuclear Fabrication

The manufacture of nuclear components at Marks Brothers is built around a highly robust quality program that is essential in that industry. Marks Brothers has been considered a top supplier on each of its nuclear contracts. It is ASME-Certified, and committed to providing the absolute best nuclear service in people, quality and production technology.

Marks Brothers’ quality systems are run under ASME Section VIII Div. 1, ASME NQA-1-1994 (NQA-1a-1995 Add.), ASME NQA-1-2000, ASME NQA-1-2008 (NQA-1a-2209 Add, NQA1b-2011 Add.), 10 CFR, Part 21, 10 CFR, Part 50, App. B, ANSI/ASME N45.2, NRC Regulatory Guide 1.28, TEMA, AWS D1.1, as well as client-specific programs designed to meet customized needs.

Whether the need is for machined components, a support bracket, glove boxes, casks, impact limiters, an internal pipe coil to heat or cool, a half-pipe jacketed reactor, pressure vessels, or a series of shell and tube heat exchangers, Marks Brothers will deliver what’s required while exceeding expectations.

Pipe Coils

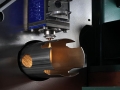

Marks Brothers manufactures pipe coils for internal heating or cooling of vessels with continuous CNC-rolling and automatic orbital welding of seams.

Each pipe is orbitally welded into the coil as it is rolled into a coil at the specified diameter and pitch.

This process ensures x-ray quality welds, provides a consistent radius and pitch, dramatically reduces material waste, and saves significant labor costs compared to trimming and fitting pre-rolled pipes into a coil.

Spot x-ray, 100% x-ray, hydrostatic testing, and documentation is provided based on specific job requirements.

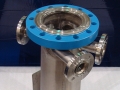

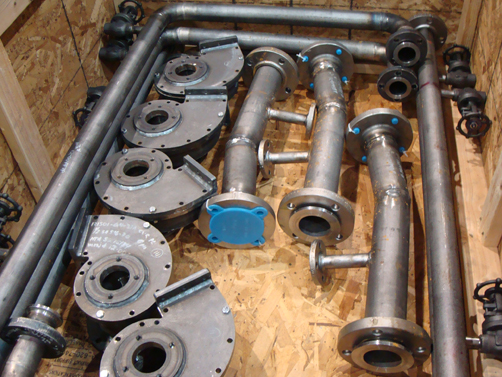

Pipe Spools / Piping Fabrication

Marks Brothers has continually invested in acquiring the most advanced equipment and ensuring its craftsmen are highly skilled. For pipe fabrication and pipe spools this investment, married with quality programs and service, brings the best pipe fabrication available. With pipe laser cutting systems, CNC-machining, CNC forming, CNC rolling, and automated orbital welding systems, Marks Brothers offers the best pipe fabricating line available. Beyond fabrication the company can provide spools in accordance with ASME Piping Codes B31.1 & B31.3, NQA-1 and client specific quality plans. Whether it is carbon, stainless, Inconel, Hastelloy, Titanium or Zirconium, Marks Brothers consistently delivers the highest quality.

Project Management

Service, as measured by clear communication, responsiveness, accurate estimates and issues resolution, is a hallmark of the Marks Brothers way. Each Project Manager has years of value-engineering experience collaborating with clients to improve their product and meet difficult schedules. Project Managers establish a production schedule in Microsoft Project, then create an Inspection and Test Plan with the quality team and the client. They then manage the job from order through delivery of the product and the documentation package. Marks Brothers establishes long-term relationships with its customers based on problem solving and delivering on its promises. Let’s work together to make your next project a success.

Quality / Inspection / Standards

Marks Brothers, Inc. has built an unparalleled reputation supplying high quality products that meet the most stringent standards. “Do it better” is not only Marks Brothers’ mission, it is its goal for every project. The diverse industries and clients Marks Brothers works with have vastly different needs, from simple components to complex nuclear skids with heat exchangers, piping and seismic loading requirements. To meet these requirements, Marks Brothers prepares client-specific process control documents for each project.

Inspection:

Marks Brothers has in-house Level II (SNT-TC-1A) certified NDE technicians and a variety of qualified subcontract NDE vendors to provide the following:

Radiography (Conventional and Digital)

Ultrasonic (Conventional and Phased Array)

Liquid Penetrant (Visible and Fluorescent)

Magnetic Particle (Visible and Fluorescent [AC/DC])

Visual (Direct and Remote)

Leak Testing (Pressure Change, Bubble and Helium Mass Spectrometry)

Marks Brothers’ quality systems provide manufacturing control in accordance with the following Codes and Standards:

ABSA

ANSI/ASME N45.2

A.P.I. 650, 620

ASME Section I

ASME Section II

ASME Section V

ASME Section VIII Div. 1

ASME Section IX

ASME Piping Codes (B31.1 & B31.3)

ASME NQA-1-1994 (NQA-1a-1995 Add.)

ASME NQA-1-2000

ASME NQA-1-2008 (NQA-1a-2009 Add, NQA1b-2011 Add.)

AWS D1.1, D1.6

NRC Regulatory Guide 1.28

P.E.D.

TEMA

10 CFR, Part 21

10 CFR, Part 50, App. B

client specific

ASME Certificates

“U”

“H”

“S”

National Board Certificates

“NB”

“R”

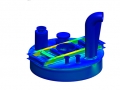

Shell & Tube Heat Exchangers

Shell and Tube heat exchanger design and fabrication is a significant part of Marks Brothers’ overall business. It has established itself as a leading supplier for numerous clients who recognize the value of high quality products. The capability to laser cut baffles, shells, nozzles, doublers, and tubing in addition to CNC machining, CNC rolling, CNC forming, and automated welding systems, creates a higher quality product at a lower cost.

Marks Brothers engineers provide mechanical and thermal designs per TEMA standards, and ASME Section VIII Div. 1. On nuclear projects, Marks Brothers also can provide F.E.A. for nozzle loadings and seismic requirements. (see Engineering and Design)

In addition to designing and building new heat exchanger projects, Marks Brothers has the experience and knowledge to help evaluate, alter, and or repair, a customer’s existing equipment under its“R” stamp program.

Bundle replacement

Condensers

Coolers

Desuper Heaters

Evaporators

Heaters

Ladders / Platforms

Low to high pressure

Pre heaters

Reboilers

Repairs and Retubing

Skid Packages

Solid Alloy or Clad

Straight / U Tube

Sweet water condensers

Tubular reactors

Tube & Pipe Laser Cutting

Whether it’s a simple cut pipe, a tube with a single hole, or complex cutouts with hundreds of holes, Marks Brothers is capable of supplying and processing round, square, rectangular or special shaped tubes with exceptional quality at a lower cost.

Marks Brothers has invested in a laser cutting system designed specifically for cutting tube and pipe. This allows the consolidation of multiple conventional fabrication steps into one continuous cutting process on one machine.

Reductions in downstream assembly costs are achieved by laser cutting components with tighter tolerances than conventional methods, providing better fit up, and easier, faster assembly. Marks Brothers can provide almost any configuration of holes, slots, notches or joints including the designing of tabs and slots for tubes to help fixture them for welding.

True, high production capabilities are achieved by loading the machine with full bundles of tubing. The self-feeding machine loads a tube, measures length, updates the program based on that length, checks the tube for twist, finds the weld seam, cuts the parts, and offloads the finished parts while simultaneously loading and measuring the next tube. No one is better at tube production than Marks Brothers.

Skid Systems

With solid modeling, structural fabrication capabilities, tube and pipe laser cutting, orbital welding, pipe fabrication capabilities in accordance with ASME B31.1 and B31.3 and vessels in accordance with ASME Section VIII Div. 1 give Marks Brothers the ability to build a wide array of skid systems. Commercial, ASME, or NQA-1 skids are a routine part of what we fabricate at Marks Brothers.